What's EPS

The 3 Types of Polystyrene Foam

Expanded Polystyrene is Used for a Variety of Applications and Formed to Various Shapes.

What is generally called Polystyrene foam is divided into 3 categories (1.EPS, 2.PSP, 3.XPS) depending on the method of manufacturing. The most common one you will see in daily life is EPS. We, Japan Expanded Polystyrene Association (JEPSA), are an organization in the EPS industry.

1EPS[ Expanded Polystyrene ]

Polystyrene particle foam

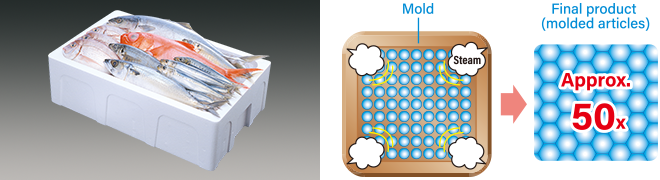

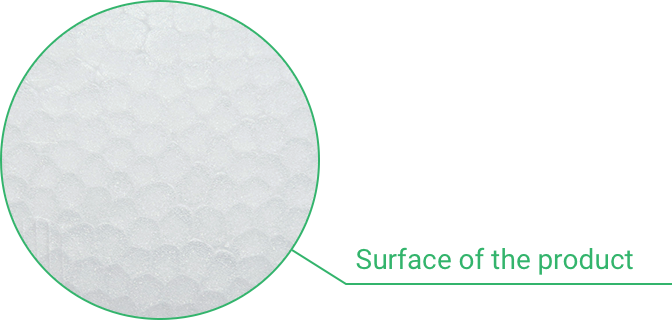

After the first expansion of the raw material (expandable polystyrene beads), EPS will be molded into a variety of shapes and can be applied for various markets. The molded bead-formed surface texture of EPS is it’s notable characteristic.

Containers for Agricultural and Fishery Products

Insulation for EcoCute

(EcoCute is copyrighted by The Kansai Electric Power Co., Inc.)

EPS Building Materials

(External Insulation)

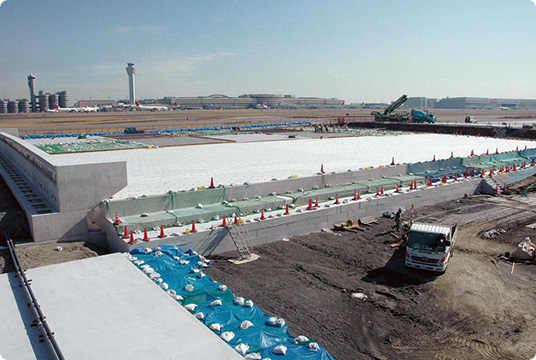

Road Construction Materials

(EPS Civil Engineering Construction Method)

2PSP[ Polystyrene Paper ]

Polystyrene foamed sheet by extrusion

This polystyrene foamed sheet is mainly used for food containers by vacuum molding. Commonly used ones are white without printing designs. There are colored and patterned trays as well.

For PSP inquires…

Japan Polystyrene Foamed Sheet Industry Association (JASFA)

https://www.jasfa.jp/

3F Tokon Building, 26 Kanda-Higashikonya-cho Chiyoda-ku, Tokyo 101-0034 Japan

3XPS[ Extruded Polystyrene ]

Polystyrene foamed board by extrusion

This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Main application is for thermal insulation materials in construction work.

For XPS inquires…

Extruded Polystyrene Foam Industry Association(EPFA)

https://www.epfa.jp/

7F Shinbashi Enter Building, 5-8-11 Shinbashi Minato-ku, Tokyo 105-0004 Japan

An Eco Friendly Material Mainly Consisting of Air

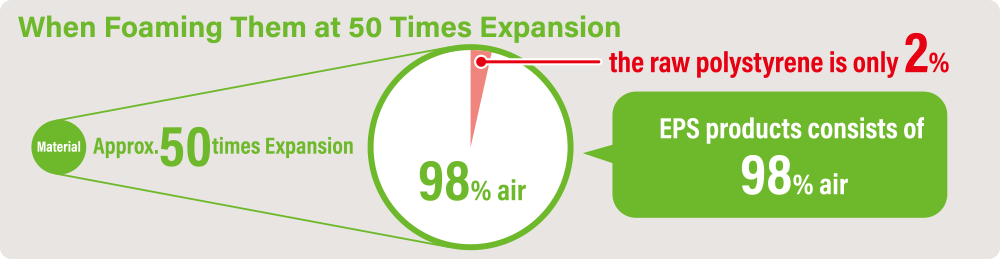

EPS is a Resource-Saving Material Composed of 98% Air*1

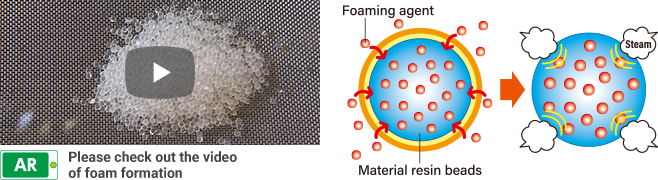

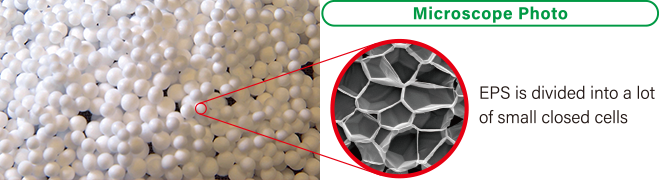

The EPS raw material is expandable polystyrene beads which contain blowing agents and whose diameter is around 1mm. When the beads are steam-heated they usually expand up to 50 times*2 of the original mass.

Because EPS is manufactured by a foaming process, 98% of total volume (mass) is constituted of air, the remaining 2% are the raw polystyrene which are derived from petroleum. Due to this small amount of raw material, it can be said that it is an excellent resource-saving product.

*1: When foamed at 50 times expansion *2: Sometimes used apporox. 3-100 times expansion foam

How EPS Products Are Made

Raw Material Resin Beads

When steam is applied directly to the raw beads, the blowing agent inside is heated and swells. The raw material resin beads also swell from this heating process.

Expanded Polystyrene Beads

Expanded materials are foamed at 50 times*1 of the original mass and becomes expanded beads consisting mostly of air.

*1: Other than 50 times expansion

EPS Molded Articles

Fill the foam beads into the mold and heat them again with steam. The foam beads go through a second expansion process and fuse to each other, which forms into the desired shape. This will become the final product.